Dear Valued Customer,

Pursuant to the Dodd-Frank Wall Street Reform Act and ensure compliance with regards to Conflict Minerals that originate in the DRC or adjacent countries, Foremost Plastic Products Company is committed to sourcing its components and products from companies that share our values around human rights, ethics and environmental responsibility. It is our intention to establish and maintain a conflict-free supply chain.

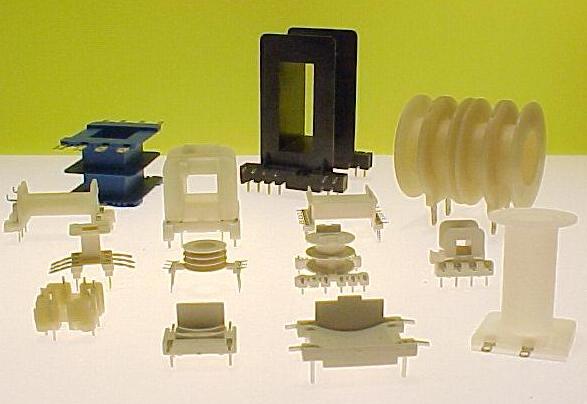

All Bobbins, parts, component or assemblies that we supply you are in compliance of the Dodd-Frank Wall Street Reform Act and do not contain Conflict Minerals that originate in the DRC or adjacent countries.